Quality

Our in-house testing capabilities include Destructive and Non-Destructive testing. Our NDT personal is level II qualified according to ISO 9712,and is working on the supervision of our level III ISO 9712.

Our Facilities for Non-Destructive Testing

Eddy current testing

Radiographic Examination

- Performed with film recording media or digital image acquisition system

Hydrostatic test

Liquid penetrant examination

Positive Material Identification (PMI)

Ultrasonic examination

Our Facilities for Destructive Testing

In-house Laboratory equipped for

- Bending tests

- Tensile strength

- Impact tests at low temperatures and room temperature

- Corrosion test according to ASTM A 262 - ASTM G48 - ASTM G28 - ISO 3651-2

- Hardness tests

- Macrographic and micrographic examinations

- Ferrite content measurement

- Chemical analysis / Products analysis

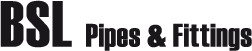

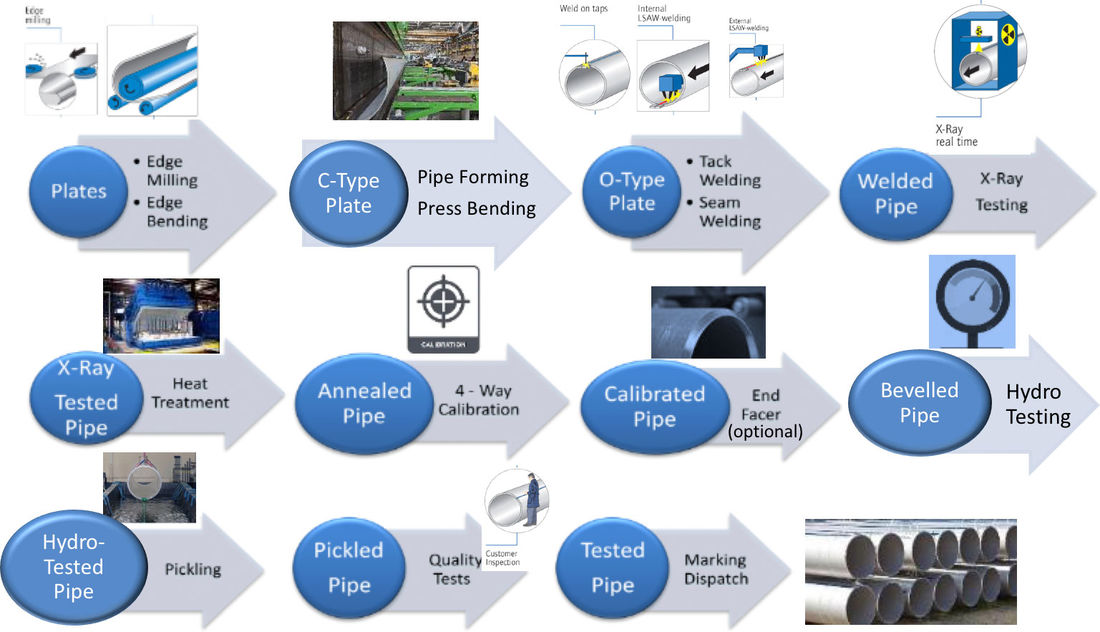

Manufacturing Process Pipes from Plate (Press Brake)MoreLess

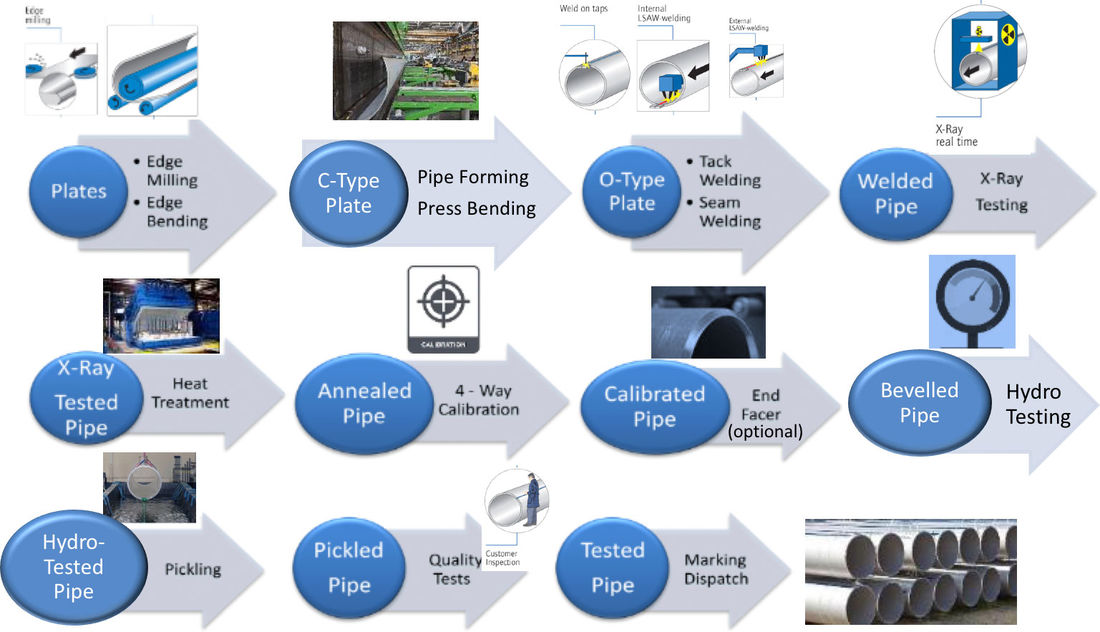

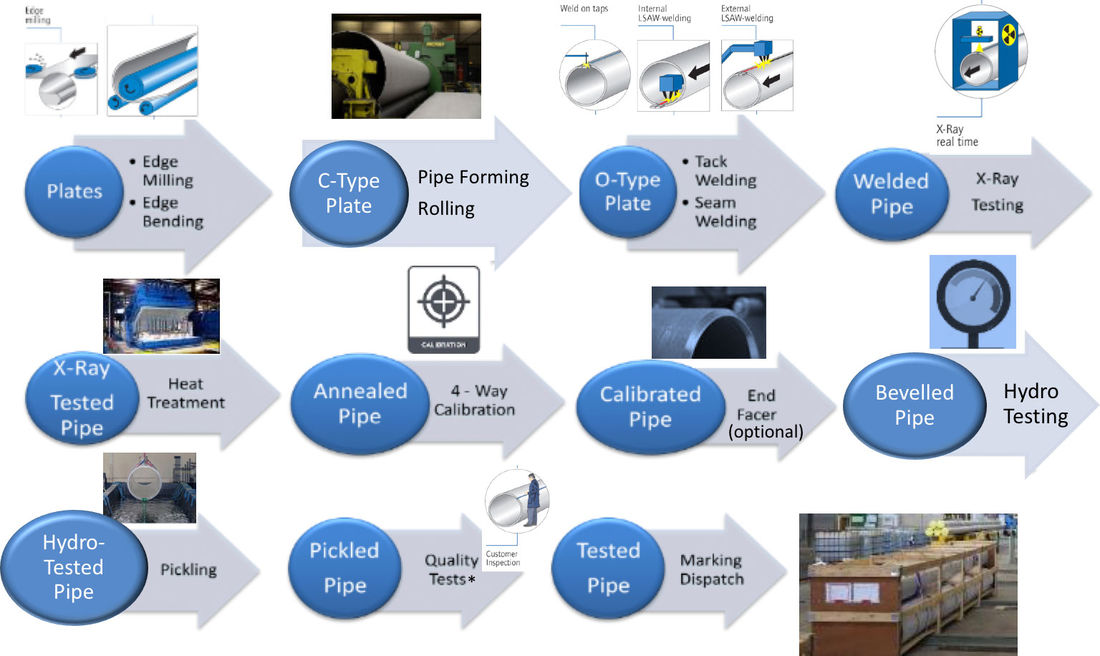

Pipes from Plate (Roller)MoreLess

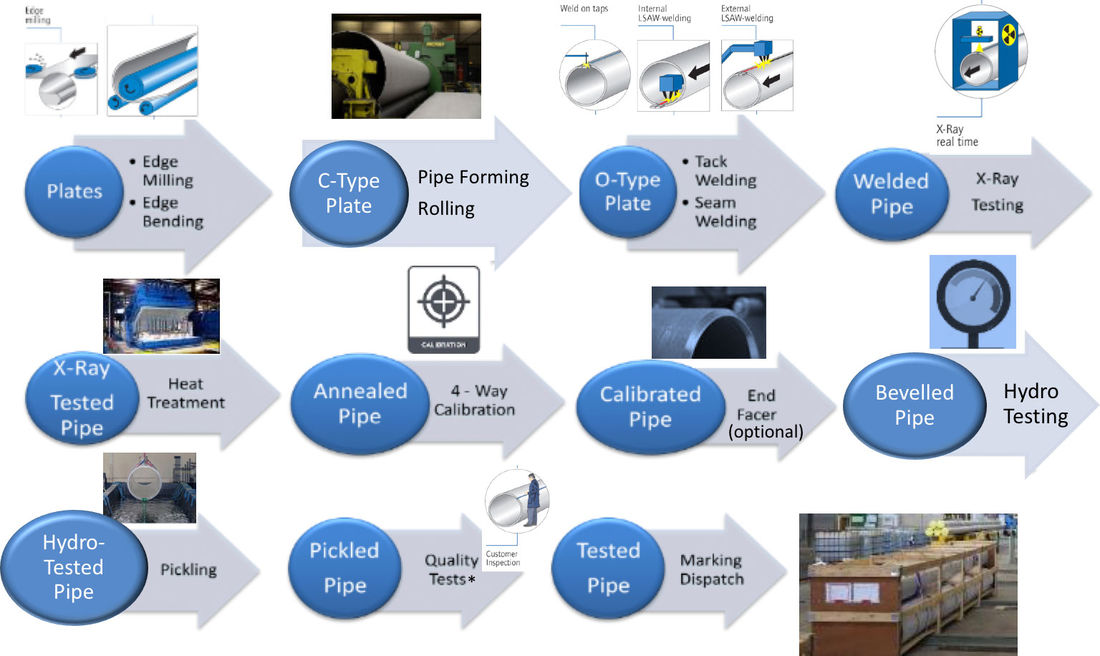

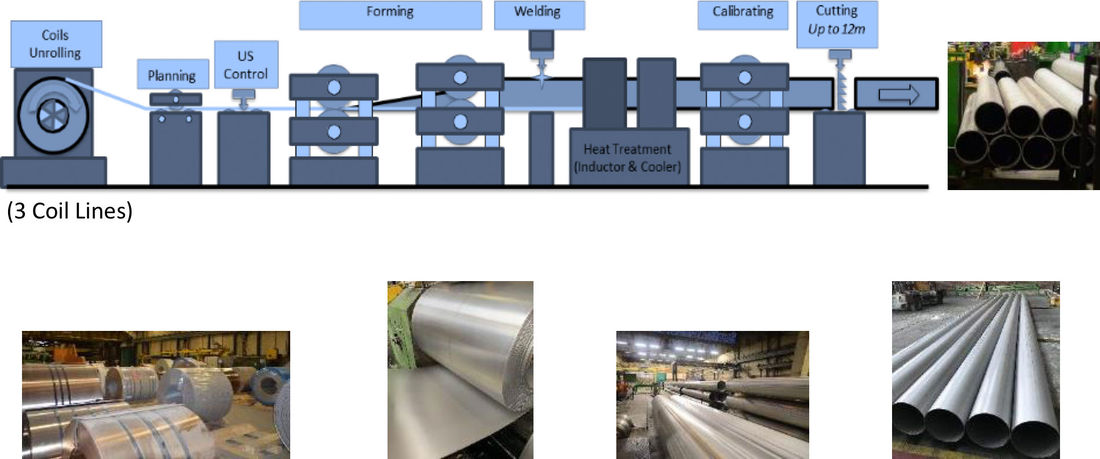

Pipes from Coil (Continuous Process)

(3 Coil Lines – OD 3“ to 20“ – WT 2 to 13mm) MoreLess

Pipes from Plate (Press Brake)MoreLess

Pipes from Plate (Roller)MoreLess

Pipes from Coil (Continuous Process)

(3 Coil Lines – OD 3“ to 20“ – WT 2 to 13mm) MoreLess

Manufacturing Standards (among others) PipesMoreLess

- ASTM A312, A358, A778, A790, A409, A928

- ASTM B 474, B 705

- EN 10217-7, 10296-2

- NF A 49-249

- EEMUA 234-2

- API 5LC

- AD-W0; AD-W2

FittingsMoreLess

- ASTM A 774, A 815, A 403

- ASTM B 366

- EN 10253-4

- EEMUA 234-7

- AD-W0 ; AD-W2

PipesMoreLess

- ASTM A312, A358, A778, A790, A409, A928

- ASTM B 474, B 705

- EN 10217-7, 10296-2

- NF A 49-249

- EEMUA 234-2

- API 5LC

- AD-W0; AD-W2

FittingsMoreLess

- ASTM A 774, A 815, A 403

- ASTM B 366

- EN 10253-4

- EEMUA 234-7

- AD-W0 ; AD-W2